quality control

Quality is our best promise and we have been maintaining it for over 20 years. Loto Garment Ltd. has a strong CAD pattern-making team inspecting the entire process from cutting and sewing to packing every day. Besides, we have an independent quality assurance staff at each production line to check over the product quality.

high quality

Advanced Equipment

Professional Team

One-Stop Solution

Over the process, Loto carries out multiple meetings and sample inspections to ensure the quality of our bulk orders:

A pre-production meeting was held for each style to hand over all the related files and requirements.

01

First piece inspection to find out defect in the earliest time.

02

Half-finished products inspection.

03

In-line inspection to ensure all defects can be avoided in time.

04

Final inspection before shipment to make sure everything in good condition for delivery.

05

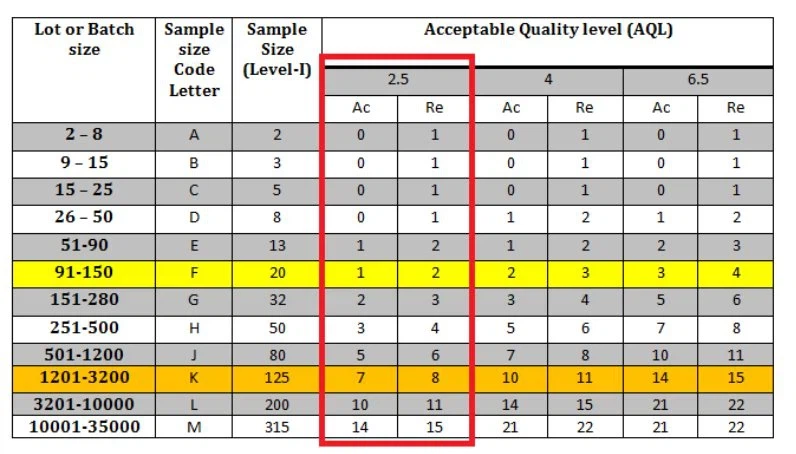

Loto garment follows AQL 2.5

- AQL stands for Acceptance Quality Limit, representing the maximum number of defective units, beyond when a certain batch is rejected.

- Importers can set different AQLs for critical, major and minor defects.

- When it comes to collecting important data into your supply chain, your products, and your business, AQL allows you to choose the percentage of defects you're ready to accept.

Loto Garment follows AQL2.5 strictly to ensure our product quality. It is the inspection standard we follow in our final inspection. Besides our regular inspections, whenever Loto notices any defects that unqualify AQL2.5, we take initiative to re-process our garments.

Cold chain transportation of